Wire Rope & Steel Cable Lanyards

A wire rope lanyard is a fixed length lanyard cable assembly used to retain, tether, or actuate components. Typical configurations use galvanized or stainless steel cable with loops, stops, or stamped eyes at each end. These mechanical cable lanyard assemblies can function as pull lanyards, safety tethers that prevent loss, or simple retention cables that keep parts connected during service.

Tyler Madison designs and builds custom wire rope lanyard assemblies and cable lanyard assemblies for OEM equipment, fixtures, and tools. Every lanyard cable is engineered around your required length, load, and environment, then manufactured as a finished assembly with the right cable, coating, and end fittings.

We help you select:

- Cable construction and diameter

- Galvanized vs stainless steel cable and components

- Coating type and color

- End fitting style and measurement points

Designing Custom Lanyard Assemblies

Tyler Madison designs and builds custom wire rope lanyards and cable lanyards for OEM equipment, fixtures, and tools. Every lanyard cable is engineered around your required length, load, and environment, then manufactured as a finished assembly with the right cable, coating and end fittings.

1. Define Function, Load & Environment

We start by selecting the correct wire rope for your load and motion requirements. Specify whether the lanyard acts as a pull lanyard, safety tether, or retention cable. Share the expected working load, any shock loads, and the safety factor you want to maintain.

Tell us how the lanyard is used and what it needs to hold.

- Is it a pull lanyard, a safety tether, or a retention cable that keeps parts together

- Working load, any shock loads, and the safety factor you want to maintain

- Operating environment, including temperature, moisture, and exposure to chemicals or cleaning agents

- Any special requirements such as low stretch, low profile terminations, or quiet operation

This information lets us choose an appropriate wire rope construction and verify that the lanyard cable has enough capacity for the job.

2. Set Length & Measurement Points

Length is usually the most critical dimension on a wire rope lanyard. We work with defined measurement points such as center-to-center of pinholes, inside loop dimension, or hardware-edge-to-hardware-edge. Together we establish practical tolerances so the lanyard fits and functions correctly. Finalizing these details ensure a proper fit in your application. This includes:

- How we measure the assembly

- What tolerances we hold

- Where the lanyard attaches at each end (hole, stud, pin, bracket, or custom hardware)

- Exact measurement points you use, such as center-to-center, inside loop dimension, or hardware-to-hardware

- Clearance to nearby parts over the full range of motion

These factors are guided by our wire rope design guides—covering recommended tolerances, measuring points, breaking strengths, wire rope stretch and more.

We define practical tolerances based on cable diameter, construction, and coating so the lanyards fit consistently when you are ready to assemble them.

3. Select cable, coating & end fittings

Once function and length are defined, we specify the construction of the lanyard itself. We match cable diameter and construction to the load and bend radius, then select coating and end fittings.

Cable Diameter impacts working load, safety factor, and flexibility. See our diameter reference guide for guidance.

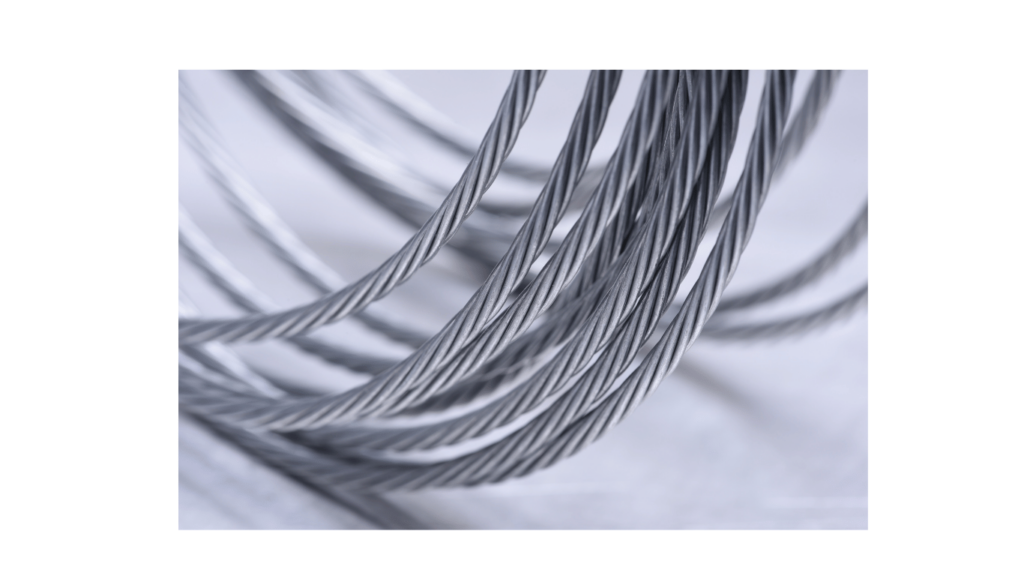

Cable Construction (braid type) affects flexibility and resistance to abrasion. Typical wire rope lanyards use 7×19 (most flexible), 7×7 or 1×19 (least flexible) galvanized or stainless cable in small diameters such as 1/16 or 3/32 inch. Learn more about cable construction.

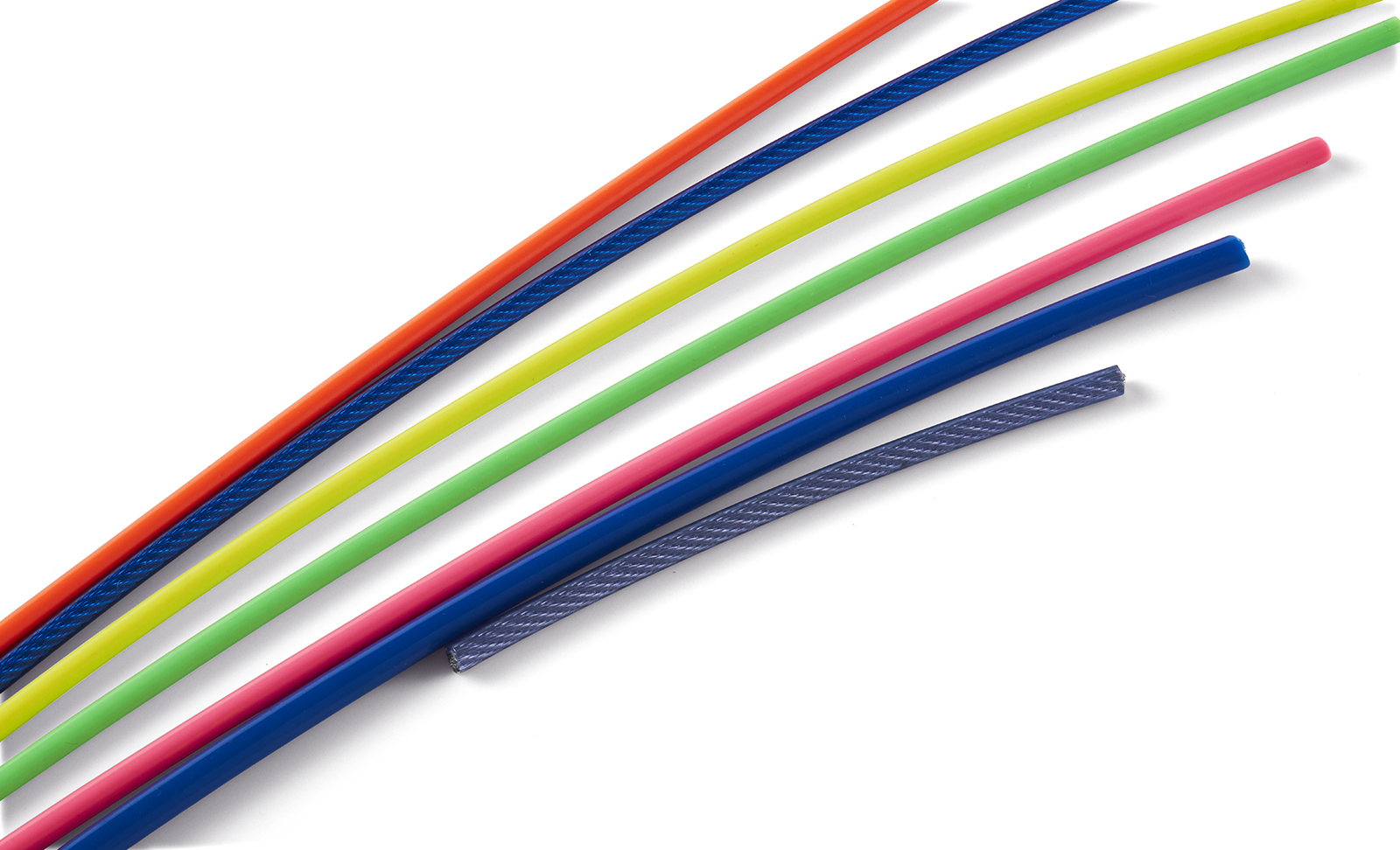

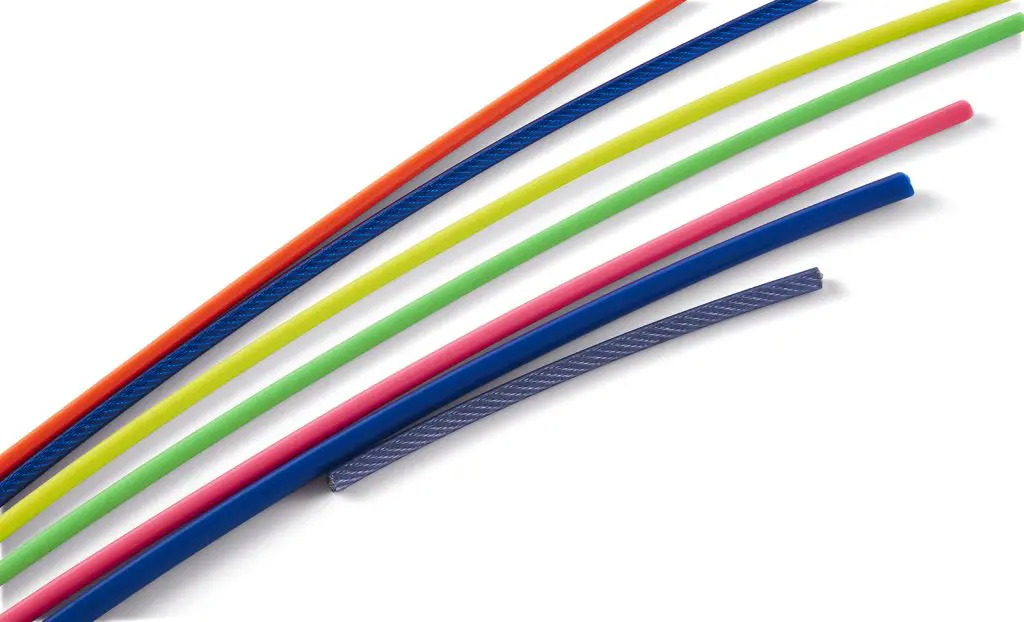

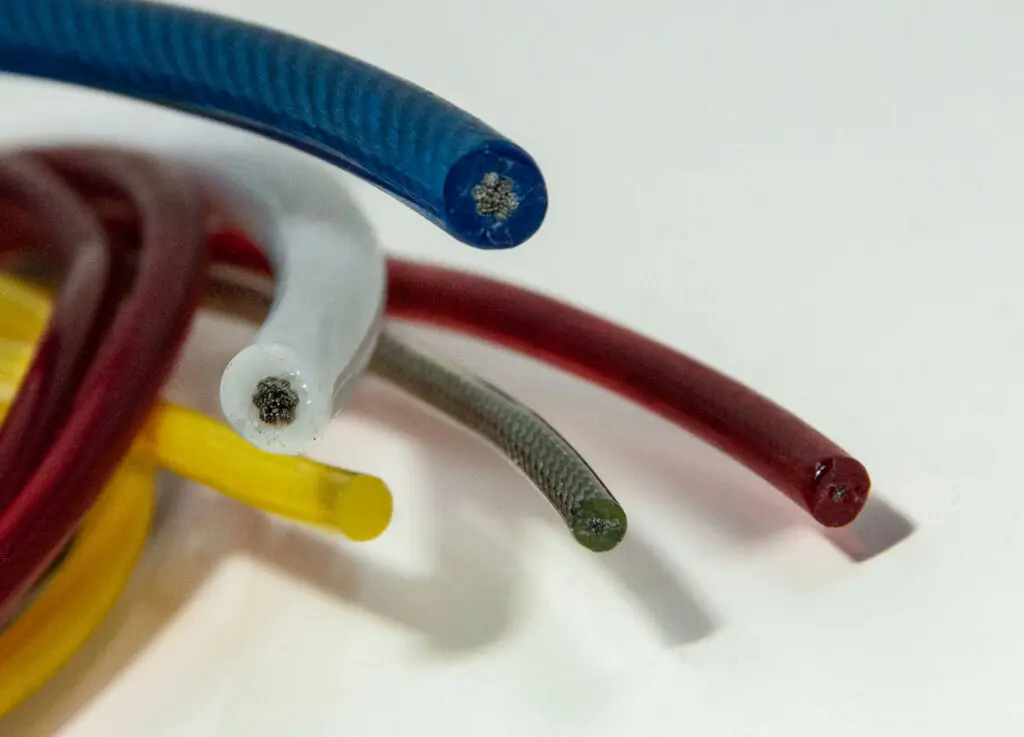

Cable Coating adds protection against wear and corrosion, and can reduce noise. Learn more about coating options. Options include:

- No coating: uncoated galvanized or stainless steel lanyards for compact routing

- Coating: Nylon, Vinyl (PVC), or Pebax; coated cable lanyards for abrasion/corrosion resistance and visual identification.

- Colors: black, white, and clear coatings are the most popular, but just about any custom color can be extruded, including translucent and glow coatings.

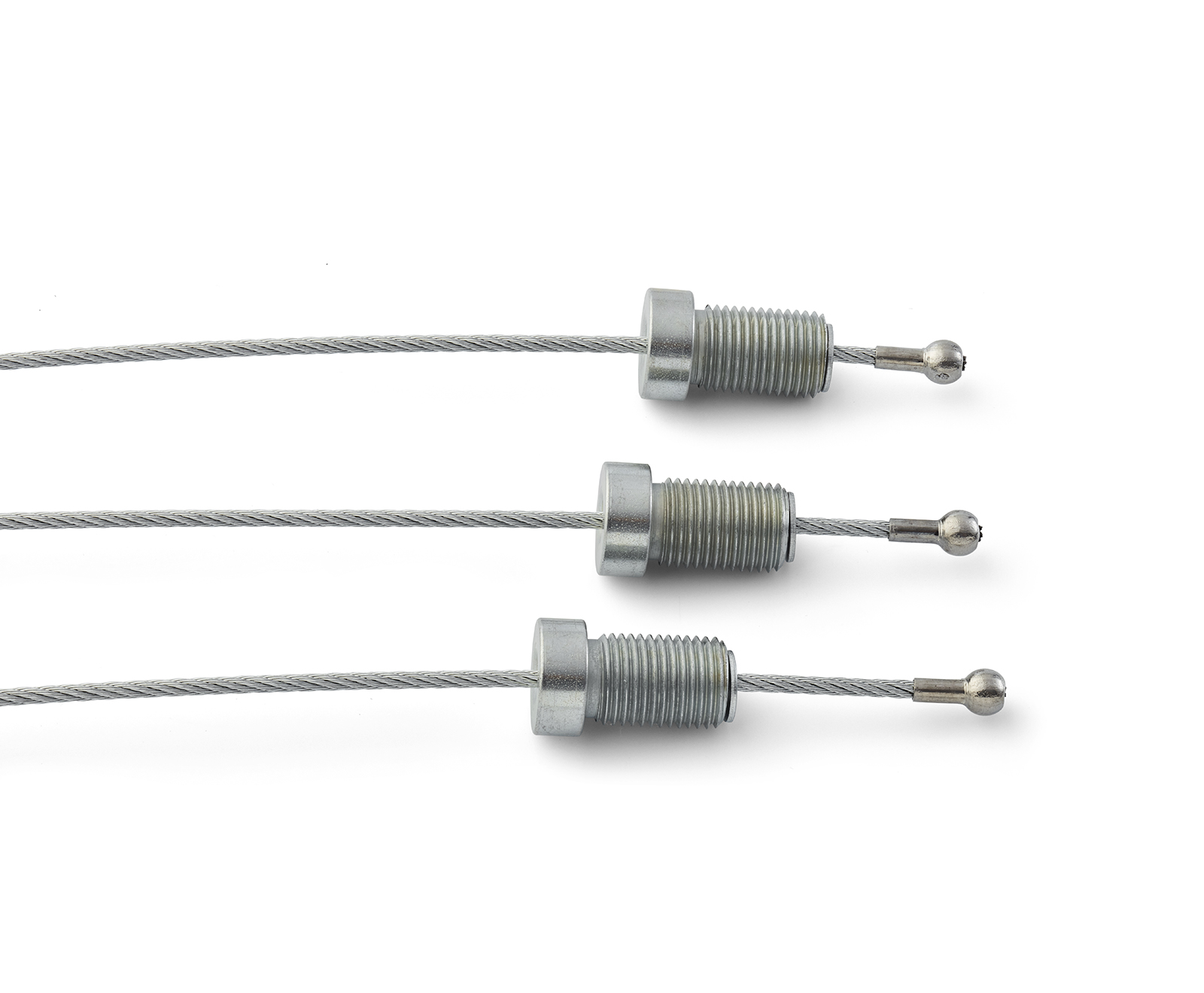

End Fittings or Terminals may include loop sleeves, stops, stamped eyes, threaded ends, thimbles, wire rope eyelets, ball shanks, handles/knobs, stops, strap forks, strap eyes, and threaded studs. Other fittings are available as well.

Custom hardware is also available that ties into your design. If your application includes hardware, let us know what type. We can add almost any type you need.

We can always recommend a diameter and construction that balances strength, flexibility and durability. The details you share on the function and forces of your assembly will allow us to help offer nuance to the design process, fill in gaps of knowledge or help you establish one if you are starting a new design.

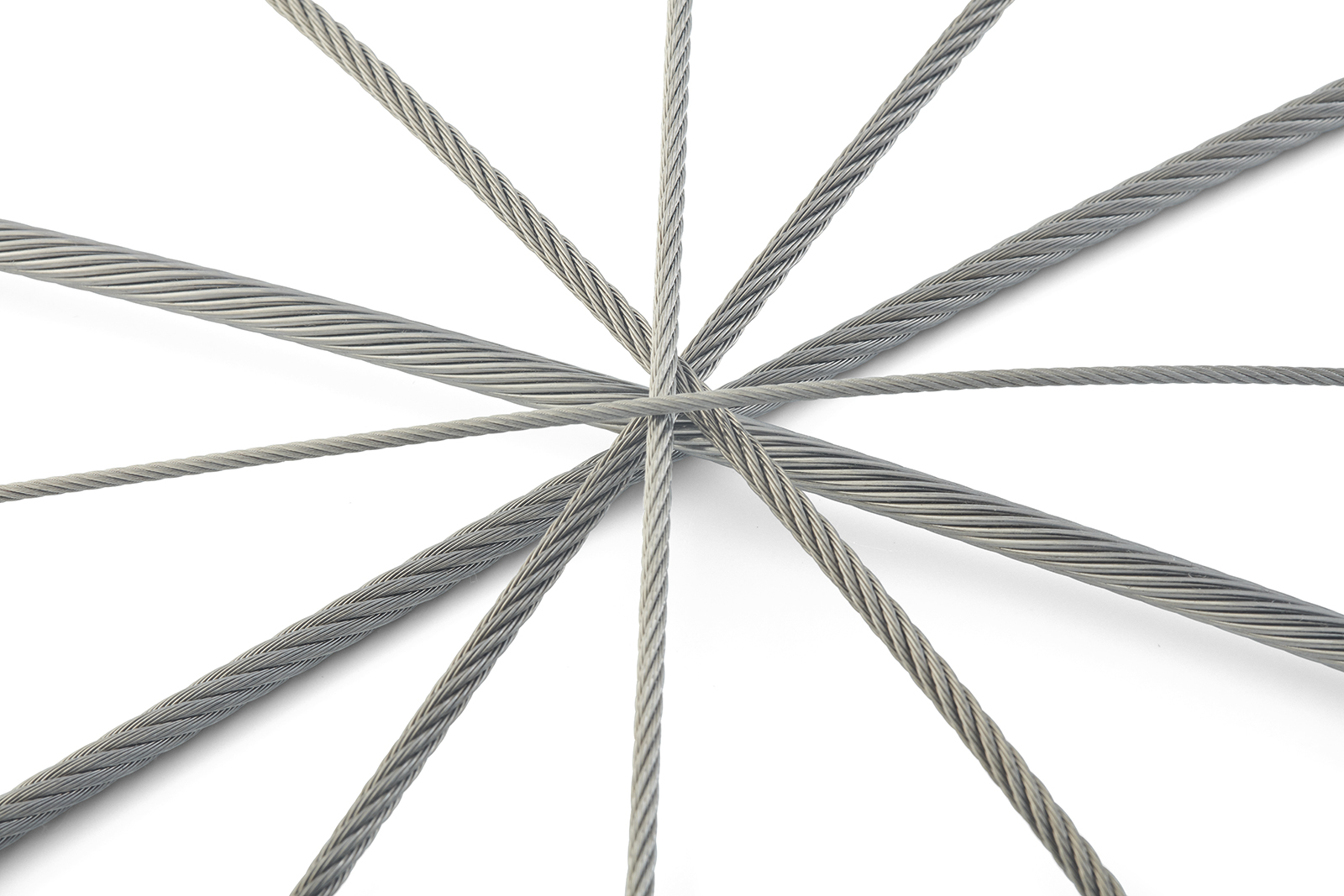

Options for Wire Rope and Cable Lanyards

Most wire rope lanyards use a simple loop-and-stop configuration, but there are many ways to tune the design for strength, flexibility, and appearance. Tyler Madison offers a range of cable, coating, and end fitting options so your lanyard cable matches the load, environment, and installation method.

Cable and Material Options for Lanyards

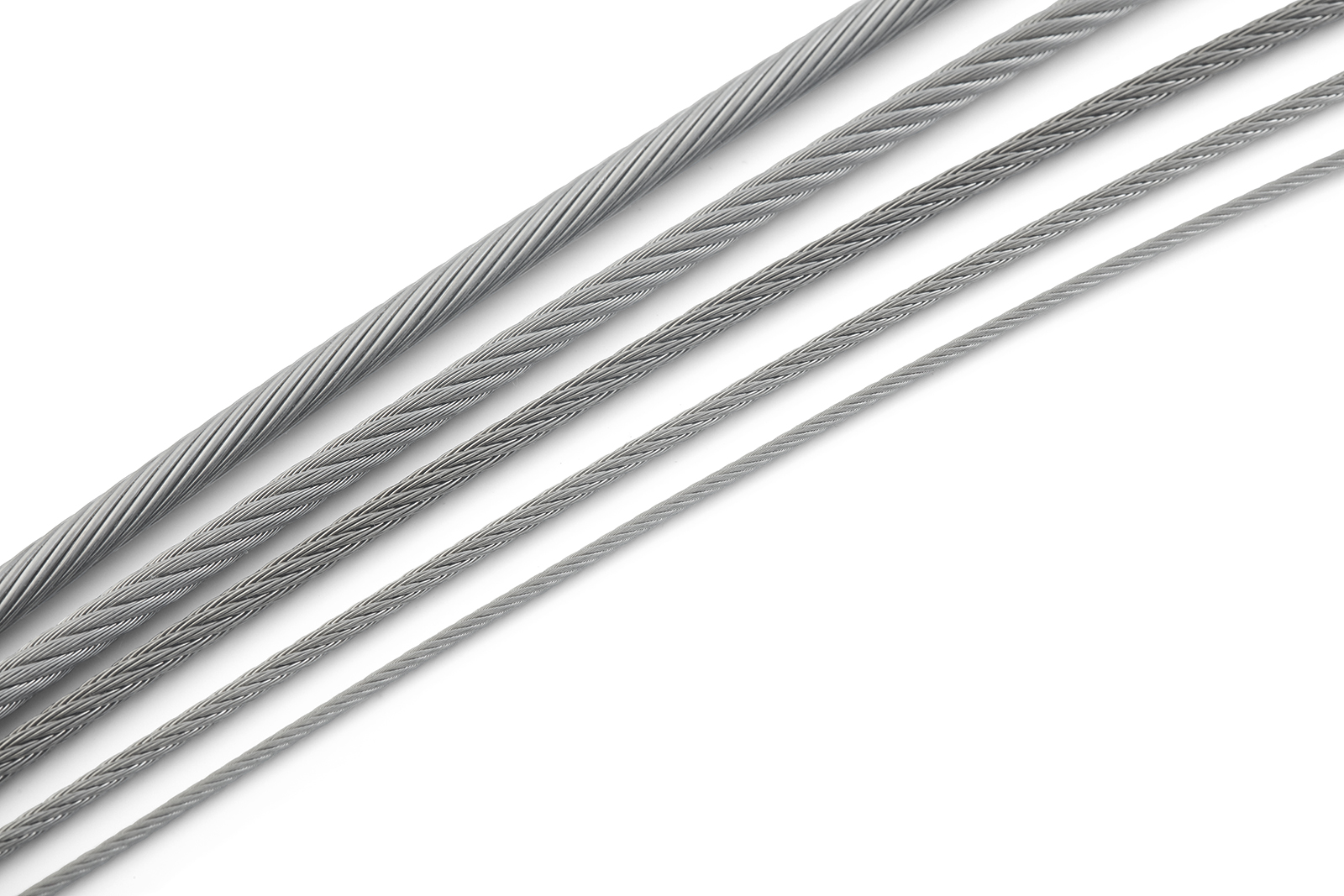

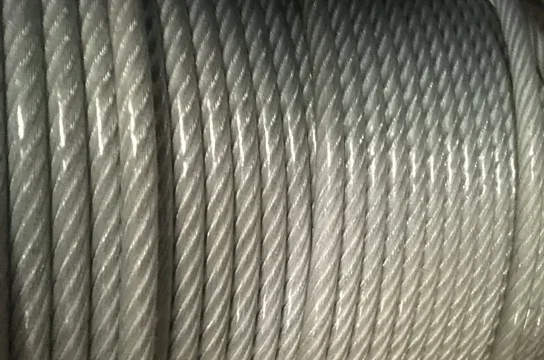

Wire rope lanyards are built from the same small-diameter cable we use in many control and restraint assemblies.

Common Lanyard Diameters

Small cable diameters such as 1/32, 3/64, 1/16, and 3/32 inch for compact, low-profile lanyards

Cable Constructions (Braid Type):

7×7 and 7×19 wire rope for a balance of flexibility and strength

Materials:

Galvanized wire rope for general-purpose industrial use, stainless steel lanyards for outdoor, marine, or corrosive environments

Coatings: Vinyl, Nylon, Bare

Colors & Identification

Tyler Madison offers many colors…. custom options avaialble.

Coating Options for Wire Rope Lanyards

Coated cable lanyards protect both the cable and the components they attach to. Bare, vinyl, and nylon coated options available.

End Fitting & Configuration Options

The end fittings and layout determine how a wire rope lanyard attaches and how it behaves in service.

- Loop-to-loop lanyards for simple attachment around pins, bolts, or through plates

- Loop-to-stop and stop-to-stop lanyards where one or both ends seat in a counterbore, bracket, or custom hardware

- Thimble-reinforced loops when the lanyard sees higher load, repeated cycling, or contact with sharp edges

- Stamped eyes, threaded studs, and custom hardware for applications that need a defined hard connection at one end

We can match existing hardware, reverse engineer an old lanyard, or help you standardize several similar lanyards across a product line

Custom Wire Rope Lanyards

Lanyard Cable Assembly Manufacturer

Tyler Madison is a leading aircraft cable lanyard manufacturer and builder of custom wire rope lanyards. We specialize in small diameter lanyards, stainless steel lanyards, tool lanyards, cable assemblies and flexible cable assemblies ¼ inch diameter and under.

Stainless Steel Cable Lanyards

At their core, these cable lanyards connect two objects together. There are an infinite number of uses for stainless steel lanyards, but the most common are: security, holding, hanging, attaching, anchoring, lifting, supporting, and pulling.

Common Uses of Wire Rope Lanyards

Our customers have used our custom wire rope lanyards and stainless steel lanyards in many different ways, including:

- Promotional displays (hanging of signs)

- Hard shell cases (lid restraint)

- Display cases (lid restraint, shelf support)

- Retail Security (security cable for electronics, clothes, expensive manuals, etc.)

- HVAC Heating and cooling duct work (support lanyards for ducts and pipes)

- Material Handling (hanging support lanyards, pulley cables)

- Specialized vehicles (security stainless steel lanyards for release pins, lid restraints)

- Lawn and garden equipment (security lanyards for release pins, lid restraints)

- Seats (seat restraint lanyard)

- Tailgates and Doors (latch lanyard, support lanyard, door restraint)

Where Wire Rope Lanyards Are Used

Applications and Industries

Custom wire rope lanyards and cable lanyards appear anywhere a component must stay attached, controlled, or within reach. Typical uses include:

- Access panel retention and doors(?)

- Instrument and tool tethers

- Safety pins and latch retention

- Pull lanyards for small actuators or releases

- Cable lanyards in fitness equipment and industrial machinery

Industries that frequently use lanyard cable assemblies include:

- Industrial equipment and automation

- Construction and agricultural machinery

- Home and Garden

- Transportation and specialty vehicles

- Medical devices and lab equipment

- Consumer and commercial products where retention is critical

Customer Reviews and Field Performance

OEMs often come to Tyler Madison when existing lanyards fail early or stretch out of tolerance. After switching to our wire rope lanyard designs, many customers report cleaner installations and fewer service calls.

OEMs often come to Tyler Madison when existing lanyards fail early or stretch out of tolerance. After switching to our wire rope lanyard designs, many customers report cleaner installations and fewer service calls.

Let us know your needs for a custom wire rope lanyard assembly; we love to hear new ideas and make them work. Send us a drawing of the wire rope lanyard you are looking to create. Or call us 1-888-638-3604 to discuss your unique application.

Talking to him further I discovered this is a family owned company that clearly does business the old fashioned way, where customer satisfaction is actually important to them. Unfortunately they didn’t have what I needed this time, but I will gladly call them agy in the future, and suggest them to my customers as well.

I’m not a company, just an individual who needed cable ends to rebuild cables on my Weilder Pro 9735 exercise machine. I was not sure they would sell to individuals but they do and I am very pleased with their product. They had the exact stamped fittings I needed and they worked great. Absolutely great service!

Value Added Services for Our Wire Rope Lanyards

One reason that so many people keep coming back to Tyler Madison Inc. for their wire rope assemblies and cables is because of the excellent value added services that we offer. These include:

- Design Assistance

- Coiling and Packaging

- Hot stamping part numbers

- Pull testing for cable strength

- Fuse Cutting

- Cable Rewinding

- Lean Manufacturing

- Kitting

- Just-in-time (JIT) Programs

- Kanban Programs

FAQs

What is a wire rope lanyard and what is it used for?

A wire rope lanyard is a short length of wire rope or aircraft cable with end fittings or loops on each end. It is used as a tether, restraint, or connector to keep components attached, control movement, or provide support in industrial, commercial, and safety applications.

What is important to consider when designing wire rope lanyards?

To design a custom lanyard, you need to consider the overall length, cable diameter and construction, material and coating preferences, the type of end fittings for each end and required strength. If your application includes hardware, let us know what type. We can add almost any type you need.

What cable sizes, materials, and coatings are available for wire rope lanyards?

Typically, these assemblies are made of 7×19 (most flexible), 7×7 or 1×19 (least flexible) cables. Materials include galvanized or stainless steel cable. Coatings include: No coating, Nylon, Vinyl (PVC), or Pebax; black, white, and clear coatings are the most popular, but just about any color can be chosen.

How do I specify a custom wire rope lanyard?

A brief description of how it will be used and what environment it will see. Drawings and photos are always helpful.

What cable sizes are recommended for wire rope lanyards?

Typically, these assemblies are made of 7×19 (most flexible), 7×7, or 1×19 (least flexible) cables

Which coating is best for outdoor cable lanyards?

Vinyl has UV inhibitors in it that protects the coating from the sun, uncoated stainless also works well in many environments.