Control Cable Assemblies

Control Cable Assemblies (also known as Push-Pull Assemblies and Pull Assemblies) are used in numerous applications requiring the transmission of force. These push pull cable assemblies are flexible enough to transmit forces in multiple directions through machinery. We have built custom push-pull control cables for the aircraft, lawn and garden, exercise equipment, medical, office equipment and automotive industries. Please see our Push-Pull Cable Design for additional information or give us a call at 888-638-2604.

Choosing The Right Control Cable Assembly

Choosing the right control cable assembly is a crucial part of the designing and engineering of mechanical components and analog systems. Push pull control cables activate equipment by transmitting physical force through machinery. Though push pull cable operation may seem easy and effortless, there is a great deal of engineering knowledge and experience that is required to design the proper push pull control cable and pull cables to fit an application exactly.

The first consideration, regarding control cables and push pull cables, is the type of treatment they must endure and withstand in the harshest of conditions. To ensure the best and most reliable performance, Tyler Madison manufactures the highest quality wire rope in the assembling, manufacturing, and producing their control cable assemblies, which are tested multiple times to guarantee exceptional performance and durability.

Control Cable Assembly at Tyler Madison

Tyler Madison is a full-service, industry leading manufacturer of custom and stock wire ropes, cable assemblies and accessories. Our affordable products and advanced manufacturing abilities make us an excellent choice for all of your wire rope and cable needs. We offer design and engineering, and we can even create functional prototypes before starting production. Whether you need a customized solution or a product from our inventory, we’re ready to help you!

Common applications for custom push pull cables

Accelerating

Actuating

Braking

Choke

Controlling

Cycling

Regulating

Steering

Types of Control Cable Assemblies

There are two types of Control Cable Assemblies:

Push-Pull Assemblies which are used when the transmission of force is required in both directions of the assembly travel. A choke on a lawn mower engine is a good example of this.

Pull Assemblies which are used when the transmission of force is needed in only one direction. Think of the hood release on your car.

Push-Pull Cable Assemblies

Custom push-pull assemblies offer multidirectional control for precise and accurate control of mechanical motion. The basic design and function of push pull assemblies makes them flexible and adaptable to fit into a wide variety of applications. The solid wire fittings of push pull assemblies make it easy to attach them to an assortment of connecting points on equipment, complicated control systems, or automated machinery.

The variety of hardwired end points of push pull assemblies ensures a secure and reliable connection to any type of device. The versatility of push pull assemblies offers a dependable way of motion transmission between fixed points or ones that constantly change their relative position.

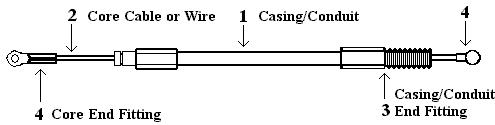

Push-Pull Control Cable

Push-pull control cables are flexible mechanical cables used to transmit motion and force in applications where precise control is required. These cables are designed to push and pull, enabling remote or difficult-to-access operation of mechanisms. They're essential in applications where remote and precise control of a mechanism is required. Their ability to transfer motion and force efficiently makes them suitable for a wide range of industries and uses.

Pull Assemblies

Pull Assemblies are used when the transmission of force is needed in only one direction. Think of the hood release on your car.

The unique nature of pull assemblies requires attention to the specific requirements of the application. The single direction of a pull assembly may give the impression that it is a type of device that has a simple and straight forward operation. There are other considerations that must be examined when creating a pull assembly.

The most important factor related to pull assemblies is the load being applied to the cable. The stroke length and stretch of the cable determine the potential pulling ability of a pull assembly. If there is too much stretch, the cable won’t be able to activate the device. In the design phase of a pull assembly, Tyler Madison’s expert engineers closely examine the pull assembly’s function to ensure proper performance.

Conduit Bowden Options

Cover: Vinyl, HDPE or uncovered wound wire

Liner: HDPE, or unlined

Braid: wound music wire, or braided and encased in polymer coating

Conduit End Fitting Examples

Inner Wire

When thinking about the inner wire to use in your push pull control cable, there are a number of options to consider. Even the lightest type of load requires a solid wire with core materials that are designed to fit the application. It is important to know that loads are the greatest in the pull direction, which is a major consideration when a push pull cable is being designed.

Cable Material

Galvanized steel or stainless steel

Cable Construction

Typically, these assemblies are made of 7 x 19 (most flexible), 7 x 7, or 1 x 19 (least flexible) cables

Conduit

Most often our customers will opt for uncoated cable as it will create the least amount of friction inside the conduit, and will extend the life of the control.

Length

There really isn’t a minimum or maximum length, just let us know your application

Ends Fittings or Terminals

We have a large selection of end fittings, including balls, ball shanks, sleeves, stamped eyes, stops, thimbles, handles/knobs, strap forks, strap eyes, and threaded studs. Others options are available as well.

Industries for Push-Pull Cable Controls

Push pull controls are important components in many different industries. Automotive, aerospace, heavy equipment and more all used variations of push pull control assemblies to adjust mechanisms and activate certain parts during operation. Quality cable assemblies makes all the difference in the lifetime performance of these parts.

In the current computer age we find ourselves in, control cables have become an essential part of programming automated equipment. The reason control cables are so essential is due to their versatility and ability to be inserted into any process knowing that they will perform accurately and flawlessly.

More Products

Maybe you’re looking for more than push pull controls. If so, you’ve come to the right place! At Tyler Madison, we also manufacture things like wire rope lanyards, wire rope cable assemblies, conduits, terminals and other related wire rope hardware. No matter that type of mechanical product that you are building or fixing, it’s likely that you can find all the cable and wire rope you need at Tyler Madison. Our advanced machining techniques and skilled team even make us capable of manufacturing complex custom control cable parts for you!