Bowden Cables & Control Cable Assemblies

A Bowden cable is a flexible control cable that transmits mechanical force by having an internal wire that glides through an outer flexible casing. At Tyler Madison, every Bowden cable control system is custom engineered around this basic concept, with each assembly built from the same four core components.

There are 4 main components

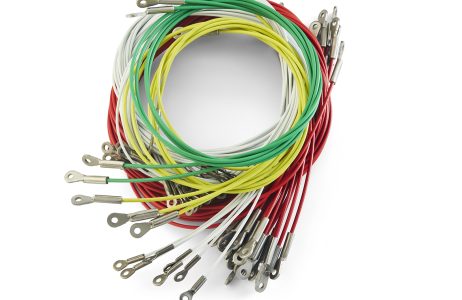

- Conduit or casing

- Conduit fittings

- Inner wire or wire rope

- Wire rope end fittings

These four components form the core of every Bowden cable control system. If your application needs positive motion in both directions, a push pull control cable assembly is usually a better fit.

Need help selecting components? Talk to an engineer.

Our extensive knowledge and experience with Bowden cables enables us to produce both standard and specialized Bowden cable assemblies for a wide range of industrial clients.

Building Your Bowden Cable Control System

When you partner with Tyler Madison, we follow a proven three step process for Bowden cable control systems that mirrors how we construct our conduit assemblies. We match the inner cable, conduit, and hardware to your mechanical and environmental requirements so your Bowden cable assembly works as intended from day one..

1. Choose or Determine End Fittings

End fittings define how your inner wire connects to your handle, lever, latch, bracket, or actuator. They also help determine which inner wire diameter makes the most sense for your build. Most Bowden cable control systems use a few common inner wire sizes:

- 3/64 inch and 1/16 inch inner wire (widely used across many conduit styles)

- 3/32 inch inner wire (typically paired with larger conduit for higher loads)

- Larger than 3/32 inch is available for custom designs when the application requires it

What we confirm in this step:

- The connection style on both ends (ball, clevis, threaded stud, loop, stamped eye)

- Your pull load and expected cycle life

- Material needs (galvanized vs stainless, corrosion exposure, heat, washdown)

- Any packaging limits that affect fitting size or orientation

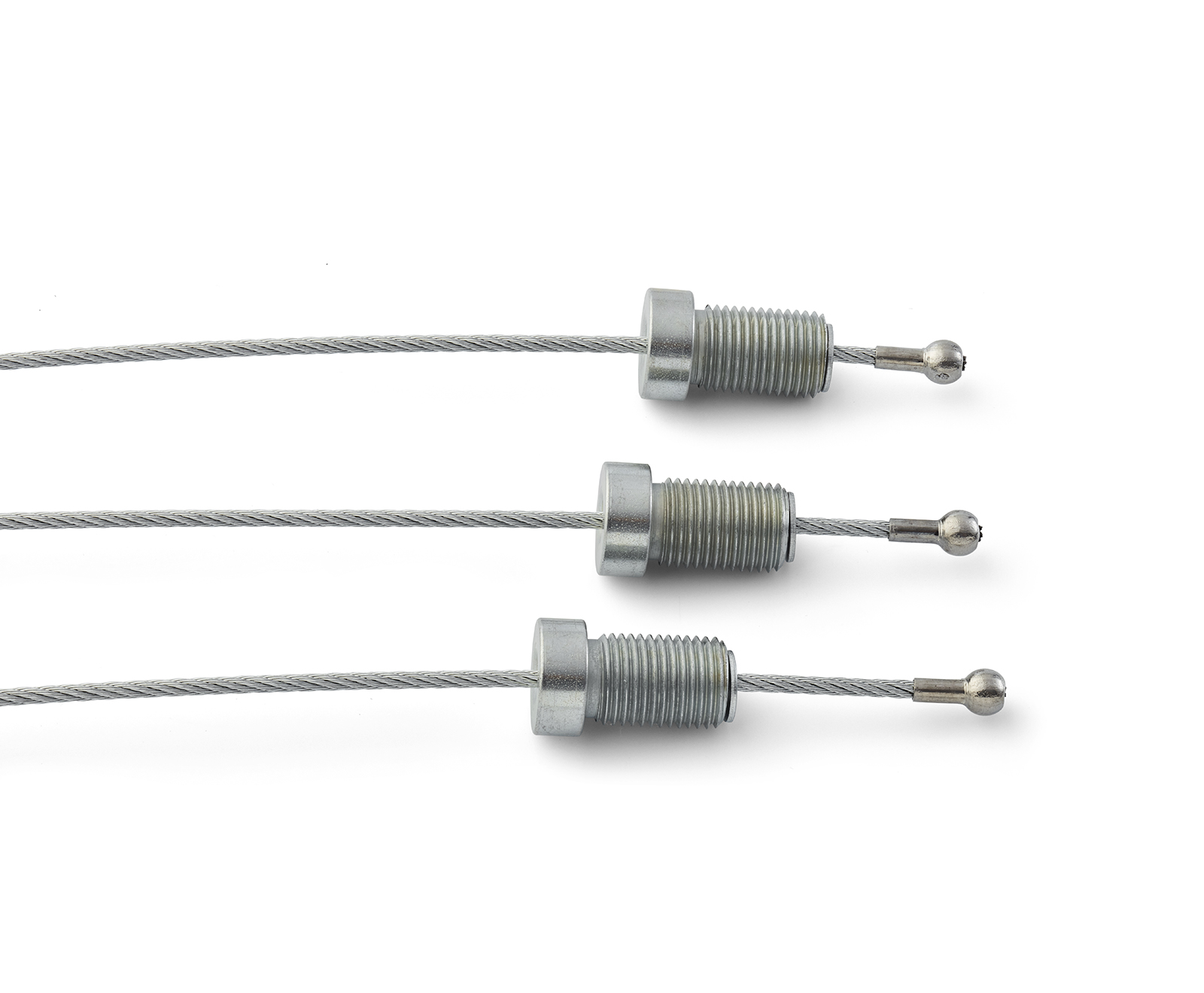

2. Choose Conduit Fittings

Once the inner wire and end fittings are defined, we match the conduit and conduit fittings that hold the system together. The conduit supports the inner wire, protects it through routing, and helps control friction and feel. Conduit fittings terminate the conduit and provide mounting, retention, and adjustment where needed.

Common Conduit Fittings

- End caps, ferrules, and retainers that secure the conduit at each end

- Threaded conduit fittings, bulkhead mounts, or snap-in styles for mounting through panels and brackets

- Adjusters or threaded hardware when you need fine tension and travel control

- Snap rings or threaded studs

Materials

- Material selection based on the environment (brass, galvanized steel, stainless steel)

- Threaded end terminals: made up of brass, galvanized steel, and stainless steel.

- Chromium plated or galvanized end caps

3. Confirm Lengths and Required Travel

The final step is confirming cable length and travel so the assembly installs cleanly and performs consistently in production. We will align on how you measure your Bowden cable, where the reference points are, and how much stroke (draw length) the system needs.

What we typically need from you

- Overall length and the exact measurement points you use

- Required stroke or draw length (how far the inner wire must move)

- Routing details (bend radius, clamp points, tight turns, moving interfaces)

- Return spring details, if applicable (force and location)

- Tolerance targets, build quantity, and whether this is prototype or production

Quick summary of the process:

End fittings → inner wire diameter → conduit size → conduit fittings → final lengths and draw length

Design Tip:

- Design tip: The more we know about your pull load, routing, return spring, and how you measure cable length, the easier it is to engineer a Bowden cable that installs smoothly and operates the way you expect.

Need a Starting Point?

Send us your print, sample, or basic requirements and our engineering team will help you refine the right cable size, conduit, end fittings, and tolerances for your Bowden cable control system.

Visualize Your Next Bowden Cable Control System

See how Tyler Madison turns specs into real-world solutions. Cables engineered for your application. Ready to design yours? Request a custom Bowden cable assembly.

Key Features & Benefits

Key features, advantages and benefits of Tyler Madison’s Bowden cable control systems.

Flexible Conduit Routing

Custom-length routing with low friction for pull control around corners and through tight spaces.

Durable Materials

Galvanized or stainless steel inner cable and high quality conduit for strength and corrosion resistance.

Custom End Fittings

Choose from stops, sleeves, clevises, threaded studs, knobs, and other hardware to match your mechanism.

Smooth Pull Control

Lined conduit and matched components help reduce friction and provide consistent pull feel over the full stroke.

Low Maintenance

Quality wire rope, conduit, and fittings support long-term performance with minimal adjustment.

Bowden Cable Supplier & Manufacturer

Tyler Madison is a full-service manufacturer of custom control cable assemblies, including Bowden cable, push pull cables, wire rope assemblies, and related hardware. Our affordable products and advanced manufacturing capabilities make us a strong partner for your control cable needs.

We provide design and engineering support and can create functional prototypes before starting production. Whether you need a custom Bowden cable assembly, a complete Bowden cable control system, or cable conduit as a component, our team is ready to help.

Why Work With Tyler Madison for Bowden Cable

Tyler Madison is a dedicated control cable assembly manufacturer. Bowden cable is part of a larger offering that includes push pull cables, lanyards and wire rope assemblies.

As a US manufacturer, we ensure the required function and form for the end user by selecting the right components for the job. We also specialize in creating micro Bowden cables. Our customized Bowden cables, including micro variants, which are used in the robotic and medical industry.

Our goal is to deliver Bowden cable assemblies that fit your equipment, your environment, and your production schedule.

We Help OEMs:

- Select the right cable, conduit, and fittings for their loads and routing

- Prototype and test Bowden cable control systems before full production

- Consolidate sourcing for control cable assemblies and cable conduit

- Scale from small runs to high volume OEM programs with consistent quality

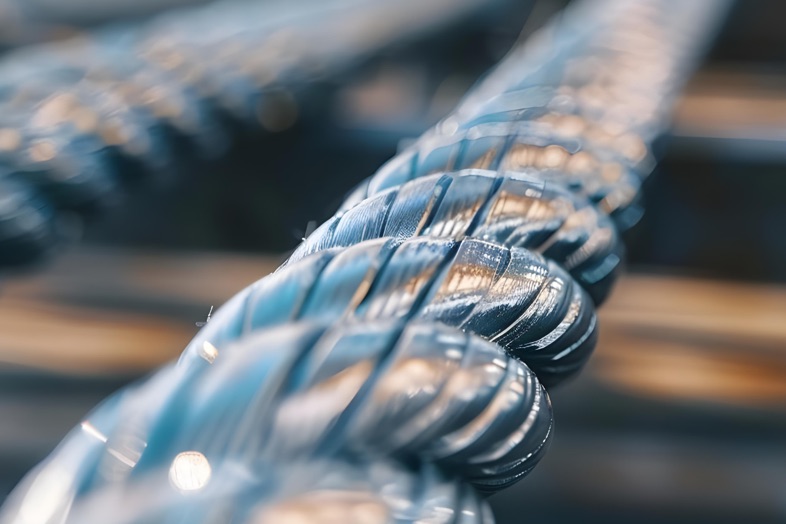

What Sets Our Conduit Apart

At Tyler Madison, we take pride in offering premium Bowden conduit that outperforms standard alternatives on the market. The Bowden conduit we sell offers several key advantages over the standard options.

Tyler Madison Conduit:

- Fewer Splices, Less Waste: Splices occur every 1000-2,000 feet, ensuring more usable length and less waste.

- Consistent Outer Coating: Features a uniform polymer thickness, providing exceptional durability and flexibility.

- Superior Quality, More Durable: Excellent for high performance applications

- Cost Effective: Through our partnerships, we’re able to provide superior conduit at a very competitive price, making it a smarter choice for bulk purchases and high-performance applications.

Industry Standard Conduit:

- More Splices, More Waste: Splices every 150-200 feet lead to 12x more waste and reduced efficiency.

- Inconsistent Coating: Inconsistent coating can result in cracks and reduced flexibility, compromising performance.

- More Expensive, Lower Quality: When it comes to control cable assemblies, the quality of the conduit used can make or break the functionality and durability of the finished product.

Custom Bowden Cable Control Systems Designed to Meet Your Needs

Our extensive knowledge and experience with Bowden cables enables us to produce both standard and specialized Bowden cable assemblies for a wide range of industrial clients.

Bowden Cable FAQs

What is a Bowden cable control system?

A Bowden cable control system combines one or more Bowden cables with mounting hardware and actuators such as handles or levers so you can operate a device from a distance. For example, a hood release handle in the cabin pulls a Bowden cable that releases a latch in the engine bay. Tyler Madison designs and manufactures Bowden cable control systems as complete control cable assemblies.

What is a Bowden cable and how does it work?

A Bowden cable is a flexible control cable that uses an inner wire sliding inside a hollow conduit. When you pull on one end, the inner cable moves through the conduit and pulls a latch, brake, throttle, or other mechanism at the other end. The conduit supports and protects the cable and lets you route the control around corners and through tight spaces.

Do you make custom Bowden cable assemblies?

Yes. Custom Bowden cable assemblies are a core part of what we do. We can build simple prototypes, engineer new assemblies from your concept, or produce repeatable Bowden cable assemblies at production volumes. We size the cable, conduit, and fittings to your travel, load, routing, and environment.

How is Tyler Madisons Bowden Conduit different than competitors?

Many off-the-shelf control cables use conduit with frequent splices and inconsistent construction, which can create friction changes along the routing and reduce service life. Our Bowden conduit is manufactured with tighter tolerances and fewer splices, which helps deliver smoother feel, more consistent forces, and improved durability in demanding applications. Learn more about our conduit cable.

Is a Bowden cable the same as a control cable assembly?

A Bowden cable is one type of control cable assembly. It is usually a pull only design with an inner cable moving inside a flexible conduit. Other control cable assemblies, such as push pull cables, are designed to transmit force in both directions. If you are not sure which type you need, our team can review your application and recommend the right control cable assembly.

Where are Bowden cables commonly used?

Bowden cable is used anywhere you need remote pull control and the device returns on its own. Typical applications include:

- Parking brake release cables

- Hood and trunk release cables

- Throttle and choke controls on engines and power equipment

- Seat adjusters and latch releases

- HVAC dampers and vents

- Light duty mechanical controls in industrial and specialty equipment

If your mechanism has a return spring and you only need pull force, a Bowden cable is often the most straightforward control solution.

Related Products

Looking for more than Bowden cable? Explore related control cable products from Tyler Madison.

Bowden Cable Supplier & Manufacturer

Tyler Madison is a leading, reliable Bowden cable supplier and manufacturer. We’re dedicated to producing custom made Bowden cables and push-pull controls tailored to your requirements.

As a US manufacturer, we ensure the required function and form for the end user by selecting the right components for the job. We also specialize in creating micro Bowden cables. Our customized Bowden cables, including micro variants, which are used in the robotic and medical industry.

Contact us today for more information or for help in developing your specific solution.

Bowden Cables

A Bowden cable is a flexible cable used to transmit mechanical force or energy by the movement of an inner wire within an outer flexible casing. The design allows the cable to transmit force in one direction—usually pull—and is widely used in various applications where flexibility and control are required.

Bowden Cable Control Systems

Our extensive knowledge and experience with Bowden cables enables us to produce both standard and specialized Bowden cable assemblies for a wide range of industrial clients. The latest technology is being used in Tyler Madison to deliver products with the best reliability in the industry. With in-house engineering and design services, you can receive the exact Bowden cable control system you need from a single source at a reasonable price.

Bowden Cable Assembly

Bowden Conduits

A Bowden conduit is a flexible, tightly wound spring that maintains its shape through internal tension while allowing for 360-degree directional bending from its linear axis.

Unlined Bowden Conduits

Unlined Bowden conduits do not contain an internal liner but may be encased in a thin, flexible protective outer shield (or sheath).

Common sheath materials include:

- Polyethylene

- Nylon

- PVC*

*These materials are selected based on the external environmental conditions the conduit will face.

Lined Bowden Conduits

Lined Bowden conduits include a flexible plastic liner inside a tightly wound spring to reduce internal friction and improve performance in harsh conditions. Liners are especially useful in applications exposed to moisture, corrosion or severe weather conditions.

Typical Liner materials include:

- High-Density Polyethylene (HDPE)

- Nylon

- Teflon

Tyler Madison Inc.’s Bestsellers

Tyler Madison is a market leader in manufacturing custom cable of wire rope fittings, aircraft cables, Bowden cables, custom wire rope lanyards, and other steel cable assemblies.

Tyler Madison has the following range of conduits among our bestsellers:

Specifications

| Item | Diameter | Description | Lined | Cover | Fitment |

|---|---|---|---|---|---|

| 401-001 | .218 | Outer Diameter | HDPE | Vinyl | 1/16 diameter cable/wire and under |

| 401-002 | .325 | Outer Diameter | HDPE | HDPE | 3/32 diameter cable/wire and under |

| 444-002.5 | 7/32 | No liner |

Types of Bowden Cable

Lined Bowden Style Conduit

| Part # | Conduit Size (in) | OD (in) | min ID (in) | OD w/ Cover |

|---|---|---|---|---|

| 5/32″ | 0.156 | 0.064 | 0.188 | |

| 401-001 | 3/16″ | 0.190 | 0.080 | 0.220 |

| **401-001.45** (see notes below) | 3/16″ | N/A | 0.080 | 0.185 |

| 7/32″ | 0.218 | 0.093 | 0.248 | |

| 1/4″ | 0.247 | 0.100 | 0.278 | |

| 401-002 | 9/32″ | 0.280 | 0.120 | 0.310 |

| **401-002.8** (see notes below) | 9/32 | 0.270 | 0.130 | 0.350 |

| 5/16″ | 0.310 | 0.158 | 0.337 |

**401-002.8: Heavy-duty Flat wire wrap

Available Materials

Industrial cable conduit above are available with Teflon, nylon or high density polyethylene liners.

Outer cover materials include PVC, nylon and high density polyethylene. Certain conduit cable stock sizes are available immediately others have longer lead times.

Unlined Bowden Style Conduit

| Part # | Conduit Size | Dimension D | Dimension E | Dimension F | Dimension G |

|---|---|---|---|---|---|

| **444-002.3** (see notes below) | 7/32 | 0.219 | 0.094 | N/A | 0.160in |

| 401-002.5 | 9/32 | 0.280 | 0.141 | 0.310 | 0.160in |

For more information or inquiries about our steel conduit cable and conduit assemblies, get in touch with us today.

What are Bowden Cables?

A Bowden cable is a cable system in which a small stranded wire moves inside a flexible outer casing. The Bowden cable has been in use since the late 1800s and has replaced the complex cable and pulley arrangements seen in bicycles and automobiles. Its hollow exterior housing is often made of spirally wound steel wire wrapped in a plastic sheath.

The cable was initially intended to be used as part of a bicycle brake mechanism and was widely accepted by cycling enthusiasts. The original Bowden brake mechanism consisted of a braking stirrup with a set of rubber pads positioned in line with the rear wheel’s metal rim. A Bowden cable attached to a lever on the bicycle’s handlebars control the stirrup. This required professional installation in order to deliver proper and reliable braking force.

Bowden cables are essential components in many mechanical systems. They provide reliable and flexible control solutions in various industries and applications.

Bowden Cable Manufacturing Process

- The outer Bowden cable housing is made up of circular wound steel wire that has been hardened to give a strong, flexible, and incompressible outer casing. It’s wrapped in PVC to protect it from the elements, keep the lubricant in place, and for aesthetic effects too.

- End caps are then swaged on the outer spiral housing. The Bowden cables use adjusting screws in combination with end caps to keep them in place.

- Afterward, wires of required material are fed inside the casing, and the end terminals are usually threaded to fit them into the required point of application.

Spiral Housing

- To improve the smooth operation of the Bowden cable inner wire, some type of dry lubricant is frequently used. Sometimes outer Bowden housing has hollow threaded ends to allow for length modifications as necessary.

- The outer housing or spiral housing of Bowden cable is often made of a composite material that includes a tightly wrapped helix of either square, round or flat steel wires.

- To prevent rust and corrosion from accumulating on both the outside and inner steel wires, this enclosure is wrapped in plastic.

- To further limit the risk of corrosion and rust, modern versions of this cable include a plastic liner inside the housing.

Inner Wires

- The inner wire of this cable is often made up of stranded stainless steel wires, galvanized wires, and coated steel according to the customers’ requirements.

- Heavy-duty cables may also contain a solid steel wire running through the middle of the stranded wire.

- In pushing activities, Bowden cables typically have a solid steel wire inside a hollow plastic casing.

Custom Bowden Cables

All custom conduit and sheathing are made from galvanized music wire with or without covering and made from a variety of materials. Other sizes of corrugated conduit and custom steel cable conduit fittings have longer lead times depending upon size and quantity. We’re also able to provide flexible cable conduit. Learn more about our standard end fittings and terminals for our metal conduit.

FAQs

What is a Bowden cable and how does it work?

A Bowden cable is a flexible control cable that uses an inner wire sliding inside a flexible outer conduit. When the inner wire is pulled or pushed, it transmits motion around bends so you can actuate levers, latches, or valves that are not in a straight line.

What is the difference between Bowden cable vs standard wire rope assembly?

A standard wire rope assembly is usually a bare cable with end fittings that works best in straight or gently curved paths. A Bowden cable includes both the inner wire and a fitted outer conduit, which guides the motion and allows the cable to snake through tight, complex routings while still delivering smooth actuation.

Are Bowden cable vs push pull cable the same thing?

Bowden cable is a general term for a flexible cable inside a conduit. Push pull cable assemblies are designed to both pull and push with controlled column strength in the center wire. Many push pull controls use Bowden-style conduit, but not all Bowden cables are engineered for push and pull loads. We can help you select the right construction for your stroke and load.

Where are Bowden cables commonly used?

Bowden cables are widely used for throttle and brake controls, seat and hood releases, latches, clutches, and other mechanical controls in vehicles, lawn and garden equipment, industrial machinery, medical devices, and many custom OEM products.

What makes Tyler Madison Bowden conduit different from typical import control cable conduit?

Many off-the-shelf control cables use conduit with frequent splices and inconsistent construction, which can create friction changes along the routing and reduce service life. Our Bowden conduit is manufactured with tighter tolerances and fewer splices, which helps deliver smoother feel, more consistent forces, and improved durability in demanding applications.

How do Bowden cables compare to hydraulic or electronic actuation?

Bowden cables provide a simple, cost-effective way to transmit mechanical motion without fluids, power, or complex electronics. Hydraulic and electronic systems can handle higher loads and long distances but add cost, complexity, and maintenance. For many mechanical controls, a well-designed Bowden cable is the most economical and reliable solution.

What information do you need to design a custom Bowden cable assembly?

Helpful details include a sketch or CAD model of the routing, required stroke, desired actuation force, inner wire and conduit diameters, end fittings, mounting style, environment, and target life or cycle count. With that information, we can engineer a Bowden or push pull assembly that feels right and meets your performance requirements.