Control Conduit Assemblies

Tyler Madison manufacturers control cables and conduit assemblies across a wide range of industries and applications where precision, durability, and motion control are essential.

What is a Conduit Assembly?

A conduit assembly is a complete, pre-engineered system that integrates flexible conduits with end connectors, and specific fittings on a sliding pre-installed inner wire, all tailored to meet the requirements of a particular application. They’re used across a wide range of industries and applications where precision, durability, and motion control are essential.

By only offering premium quality Bowden conduit with fewer splices, consistent coating, and competitive pricing, we provide our customers with first-rate value for their control cable assemblies. Whether you’re in automotive, industrial, or medical industries, our conduit assemblies are the perfect solution for your precision motion control needs.

What Sets Our Conduit Apart

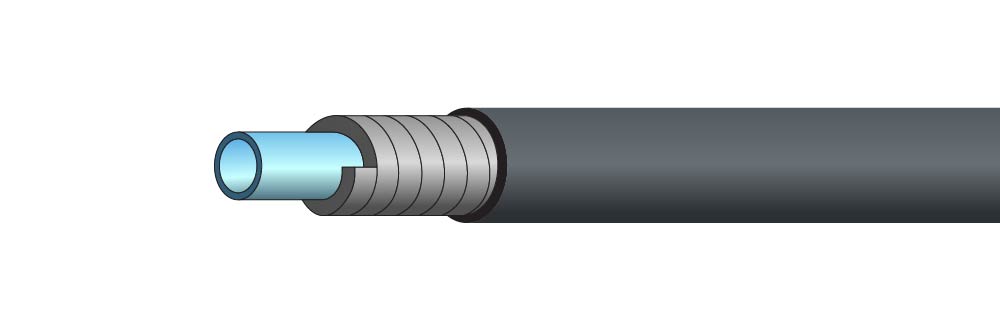

At Tyler Madison, we take pride in offering premium Bowden conduit that outperforms standard alternatives on the market. The Bowden conduit we sell offers several key advantages over the standard options.

It all begins with the quality of your conduit…

Tyler Madison Conduit:

- Fewer Splices, Less Waste: Splices occur every 1000-2,000 feet, ensuring more usable length and less waste.

- Consistent Outer Coating: Features a uniform polymer thickness, providing exceptional durability and flexibility.

- Superior Quality, More Durable: Excellent for high performance applications

- Cost Effective: Through our partnerships, we’re able to provide superior conduit at a very competitive price, making it a smarter choice for bulk purchases and high-performance applications.

Industry Standard Conduit:

- More Splices, More Waste: Splices every 150-200 feet lead to 12x more waste and reduced efficiency.

- Inconsistent Coating: Inconsistent coating can result in cracks and reduced flexibility, compromising performance.

- More Expensive, Lower Quality: When it comes to control cable assemblies, the quality of the conduit used can make or break the functionality and durability of the finished product.

Interested in purchasing our premium conduit in bulk?

To learn more give us a call or fill out a contact form. We look forward to servicing you!

Control & Conduit Assembly Design

Control and Conduit assemblies are complete, pre-engineered systems that integrate flexible conduits with end connectors, and specific fittings on a sliding pre-installed inner wire, all tailored to meet the requirements of a particular application.

Constructing a Conduit Assembly

The process of creating a conduit assembly involves:

- Determine the Push pull length, or “play” of the inner wire and cut lengths: To the exact length required for the full assembly, taking into account the stretching of end fittings when crimping.

- Attaching Fittings: Using up to 120 ton swage machines to ensure secure end connections.

- Integrating Control Cables: Ensuring smooth operation of the inner wire and minimal friction within the conduit.

Conduit Assembly Considerations

When designing a conduit assembly, consider the following:

Length and Flexibility Requirements

Ensure the conduit can handle the intended range of motion.

Durability Needs

Match the material to the environmental conditions (e.g., frequency of use, temperature, wet environments and exposure to chemicals). Our premium conduit has consistent polymer coatings to reduce cracking and increase durability when compared to the industry standard conduit.

Push, Pull or Both

Push assemblies require a solid inner wire to transfer force, while pull assemblies have a flexible wire, allowing the full assembly to be fluidly installed into complex systems, but require a spring on the wire or connected to the wire to reset the wire actuation.

Conduit Fittings

Selecting the right fittings ensures a secure connection between the conduit and other components. Key factors include:

- Material connectivity

- Size and threading requirements

- Environmental sealing needs

For more information on specific types of custom wire rope cable assemblies, take a look at these pages:

Integrating Control Cables

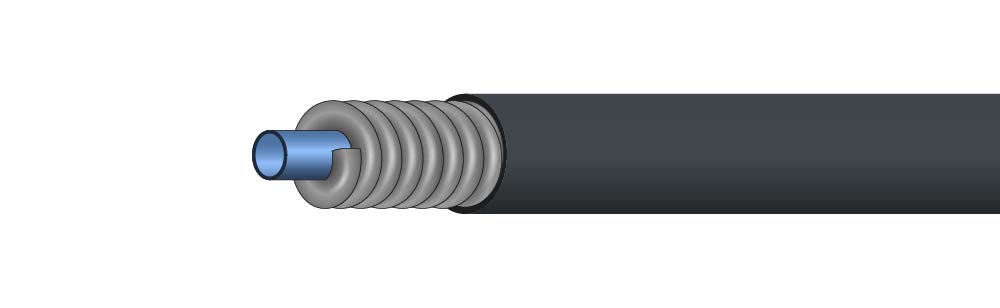

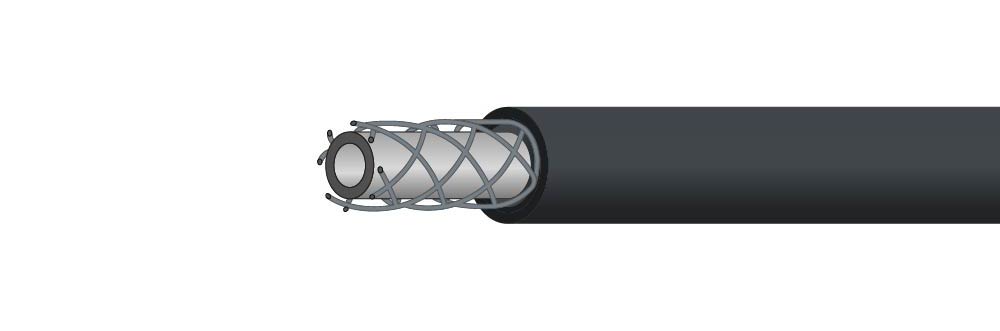

Control cables are used in any application where mechanical actuation or mechanical force needs to be used to actuate something between 2 fixed points. There are 4 main components used in the manufacturing of these assemblies. Conduit/Casing, Conduit Fittings, Wire/Wire Rope and Wire Rope End Fittings.

- Control cables

- Tension Cables

- Brake Cables

- Actuation Cables

- Throttle Cables

In addition to our custom cable assemblies, be sure to also check out our conduit cable offerings.

Important Design Considerations

Designing an effective conduit assembly requires careful attention to various factors to ensure optimal performance and longevity. Key considerations include:

- Push, Pull or Both:

- Push assemblies require a solid inner wire to transfer force, while pull assemblies have a flexible wire, allowing the full assembly to be fluidly installed into complex systems, but require a spring on the wire or connected to the wire to reset the wire actuation.

- Environmental Conditions:

- Assess the operating environment, including exposure to moisture, chemicals, extreme temperatures, or UV radiation. Selecting materials with the right resistance properties will enhance durability.

- Load and Motion Requirements:

- Consider the amount of force and type of motion the conduit will experience, such as bending, twisting, or stretching. Ensure the conduit’s flexibility matches the application’s needs.

- Cable Protection:

- Choose a conduit that provides adequate protection against abrasion, crushing, or external impact to safeguard the internal cable.

- Routing and Space Constraints:

- Plan the conduit’s path to avoid sharp bends or tight spaces that may compromise performance. Ensure proper routing to minimize friction and wear.

- Fittings and Connectors:

- Select fittings that ensure secure and reliable connections. The fittings should also provide proper sealing to prevent contaminants from entering the assembly.

- Material Selection:

- Use materials that balance strength, flexibility, and resistance to environmental factors. For instance, certain polymer coatings enhance flexibility or have chemical/UV resistance.

- Regulatory Compliance:

- Ensure the conduit assembly meets industry-specific standards and regulations for safety and performance.

- Installation and Maintenance:

- Design assemblies that are easy to install and maintain, reducing downtime and ensuring longevity.

Where Are Conduit Assemblies Used?

Tyler Madison’s wire rope and steel cable assemblies have thousands of different applications and uses. We carry a large inventory of standard and stock rope assemblies, but excel in custom cable assemblies and cable end fittings. No matter what your application or industry, contact Tyler Madison first for a quick solution to your needs.

- Automotive Applications

- Medical Equipment

- Industry Machinery

- Aerospace Systems

- Marine Applications

- Consumer Products

- Robotics

- Agricultural Equipment

- Automotive Applications: Conduit assemblies are integral to automotive control systems, such as throttle cables, brake cables, gear shift mechanisms, and hood or trunk release systems. Their durability ensures reliable performance under constant movement and varying temperatures.

- Medical Equipment: In the medical field, conduit assemblies are used in devices like surgical equipment, patient beds, and diagnostic machines, where smooth and precise control is critical.

- Industrial Machinery: Heavy machinery in manufacturing plants relies on conduit assemblies to control mechanical movements, ensuring safety and efficiency in operations.

- Aerospace Systems: Conduit assemblies play a crucial role in aircraft control systems, providing precision in critical components such as flight control cables and landing gear systems. They are also used for less flight critical applications such reclining seats.

- Agricultural Equipment: From tractors to harvesters, conduit assemblies help control systems such as throttles, brakes, and other mechanical functions in agricultural machinery.

- Marine Applications: Used in boats and ships, conduit assemblies help manage throttle and steering cables, offering corrosion resistance and durability in marine environments.

- Consumer Products: Applications extend to fitness equipment, lawn and garden power tools, and home appliances that require motion control mechanisms.

- Robotics: Robotics and automation systems depend on conduit assemblies to protect and guide control cables for precise movements in various environments.

Conduit Cable Control Assembly FAQs

What is a Bowden cable control system?

A Bowden cable control system combines one or more Bowden cables with mounting hardware and actuators such as handles or levers so you can operate a device from a distance. For example, a hood release handle in the cabin pulls a Bowden cable that releases a latch in the engine bay. Tyler Madison designs and manufactures Bowden cable control systems as complete control cable assemblies.

Do you make custom Bowden cable assemblies?

Yes. Custom Bowden cable assemblies are a core part of what we do. We can build simple prototypes, engineer new assemblies from your concept, or produce repeatable Bowden cable assemblies at production volumes. We size the cable, conduit, and fittings to your travel, load, routing, and environment.

Is a Bowden cable the same as a control cable assembly?

A Bowden cable is one type of control cable assembly. It is usually a pull only design with an inner cable moving inside a flexible conduit. Other control cable assemblies, such as push pull cables, are designed to transmit force in both directions. If you are not sure which type you need, our team can review your application and recommend the right control cable assembly.

How is Tyler Madisons Bowden Conduit different than competitors?

Many off-the-shelf control cables use conduit with frequent splices and inconsistent construction, which can create friction changes along the routing and reduce service life. Our Bowden conduit is manufactured with tighter tolerances and fewer splices, which helps deliver smoother feel, more consistent forces, and improved durability in demanding applications. Learn more about our conduit cable.

What information do you need to design a custom Bowden cable assembly?

Helpful details include a sketch or CAD model of the routing, required stroke, desired actuation force, inner wire and conduit diameters, end fittings, mounting style, environment, and target life or cycle count. With that information, we can engineer a Bowden or push pull assembly that feels right and meets your performance requirements.