Wire Rope Cable Assemblies

Leading American manufacturer of custom wire rope and steel cable assemblies for demanding mechanical applications.

Custom Wire Rope Assemblies & Custom Cable Assemblies

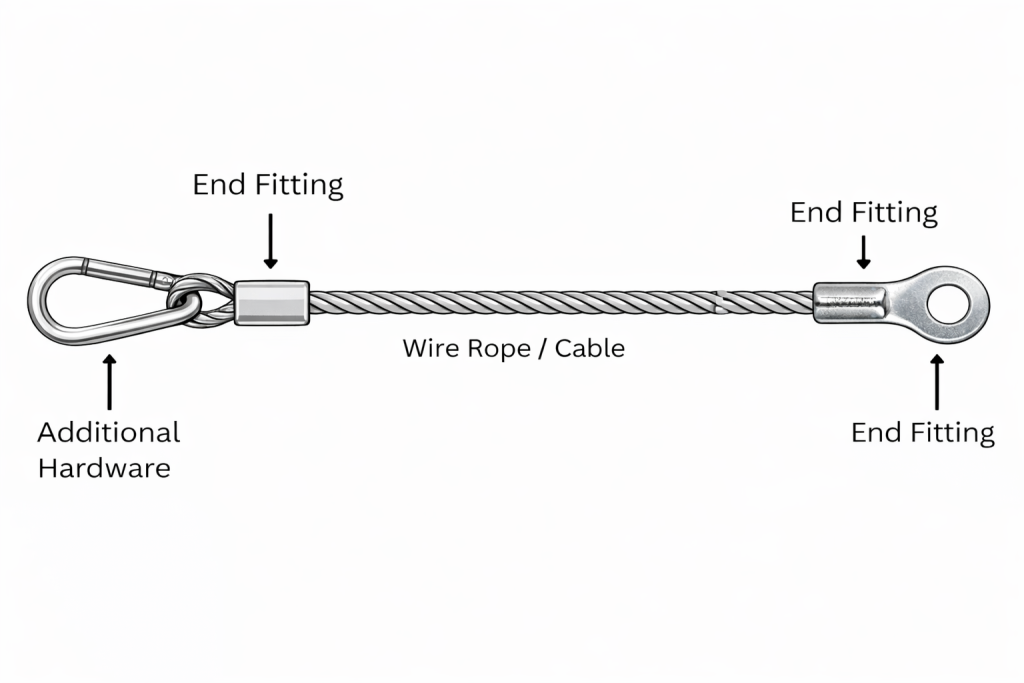

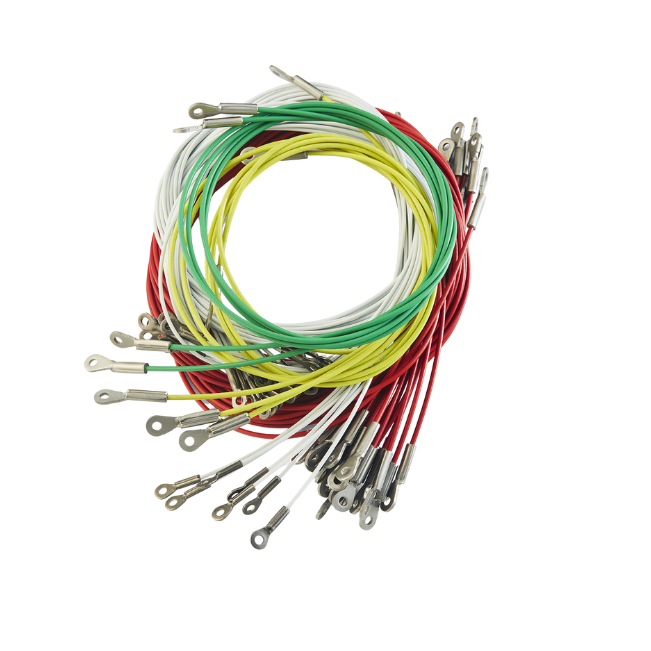

Tyler Madison is a custom cable assembly manufacturer building wire rope assemblies and custom cable assemblies to your exact requirements. Wire rope cable assemblies are pre-engineered lengths of steel cable fitted with end terminations and hardware so they can lift, secure, hang, restrain, or guide loads. Every wire rope assembly is built from three key elements: the cable itself, the end fittings, and any additional hardware.

Getting each piece right ensures your assembly can carry the required load, fit your mating components and stand up to the environment.

Building Custom Wire Rope Assemblies

Tyler Madison designs and manufactures custom wire rope and steel cable assemblies engineered for high strength, reliability, and repeatable performance. We offer standard and fully custom configurations to meet your exact load, length, and environmental requirements.

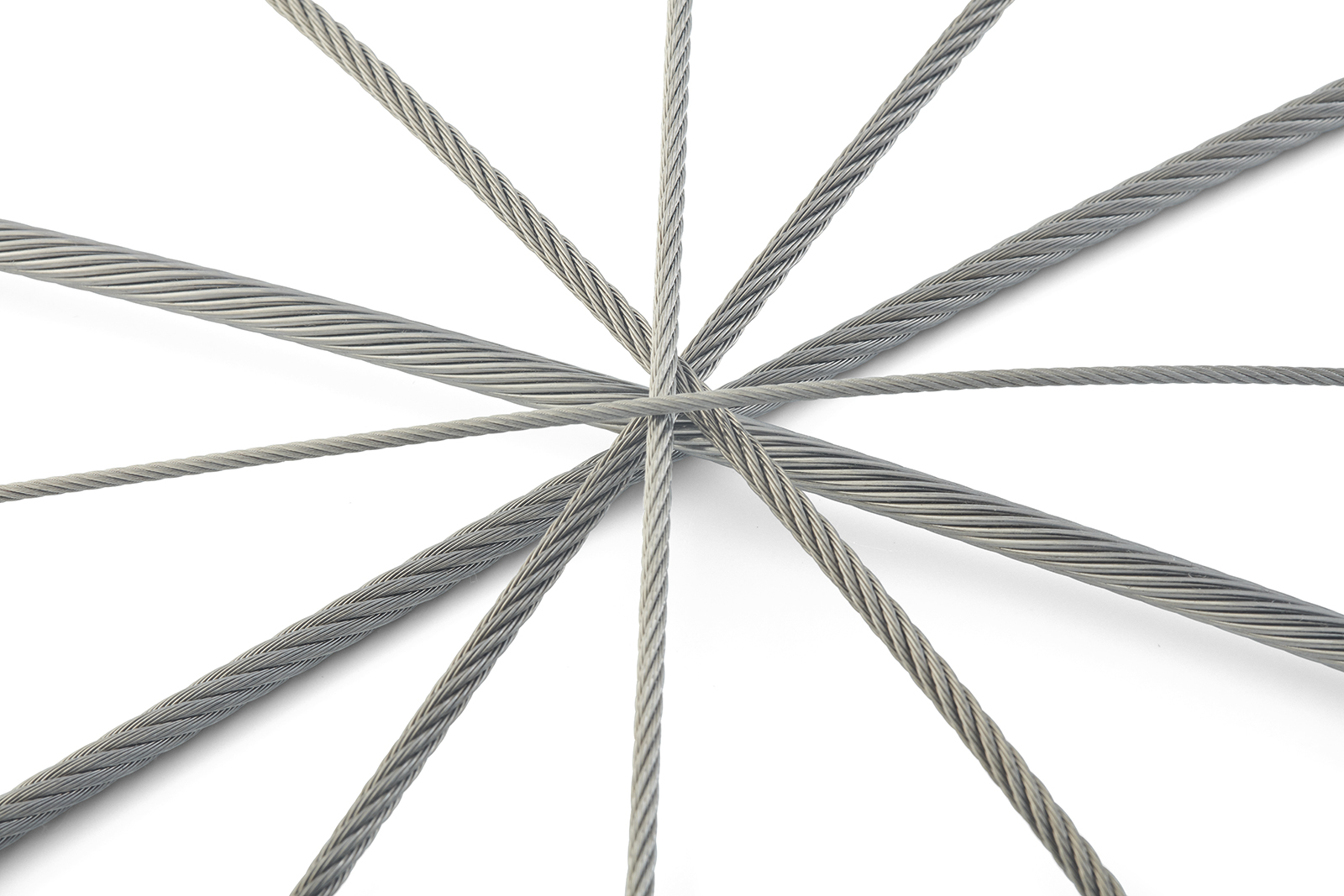

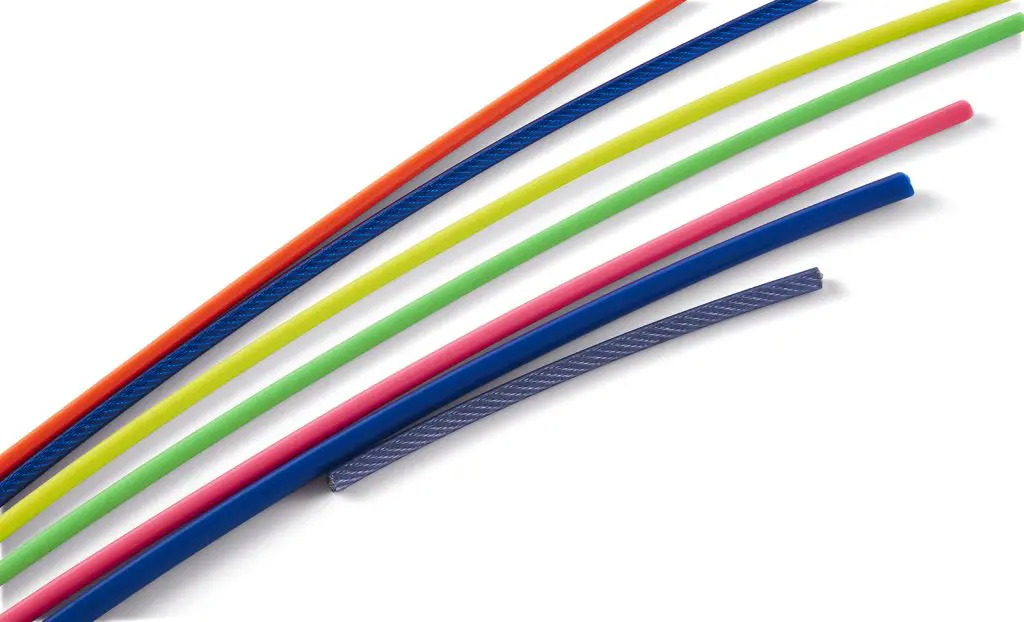

1. Choose Cable Diameter, Construction & Coating

We start by selecting the correct wire rope for your load and motion requirements.

Diameter impacts working load, safety factor, and flexibility. See our diameter reference guide for guidance.

Construction affects flexibility and resistance to abrasion. Learn more about cable construction.

Coating adds protection against wear and corrosion, and can reduce noise. Learn more about coating options.

From there we will recommend a diameter and construction that balances strength, flexibility and durability. Not sure how to choose? Check out our design guides or article on choosing the right cable for your assembly.

2. Select End Fittings & Hardware

End fittings turn raw wire rope into a functional assembly. Tyler Madison offers a broad range of standard and custom terminations. When selecting end fittings, we look at:

- How the assembly needs to attach (eye, threaded, clevis, hook, etc.)

- Space constraints at each connection point

- Required movement or articulation at the joint

- Material and finish requirements for your environment

Starting with the proper end fittings and hardware ensures your wire rope assembly attaches securely, moves the way you intend and meet your load and environmental requirements.

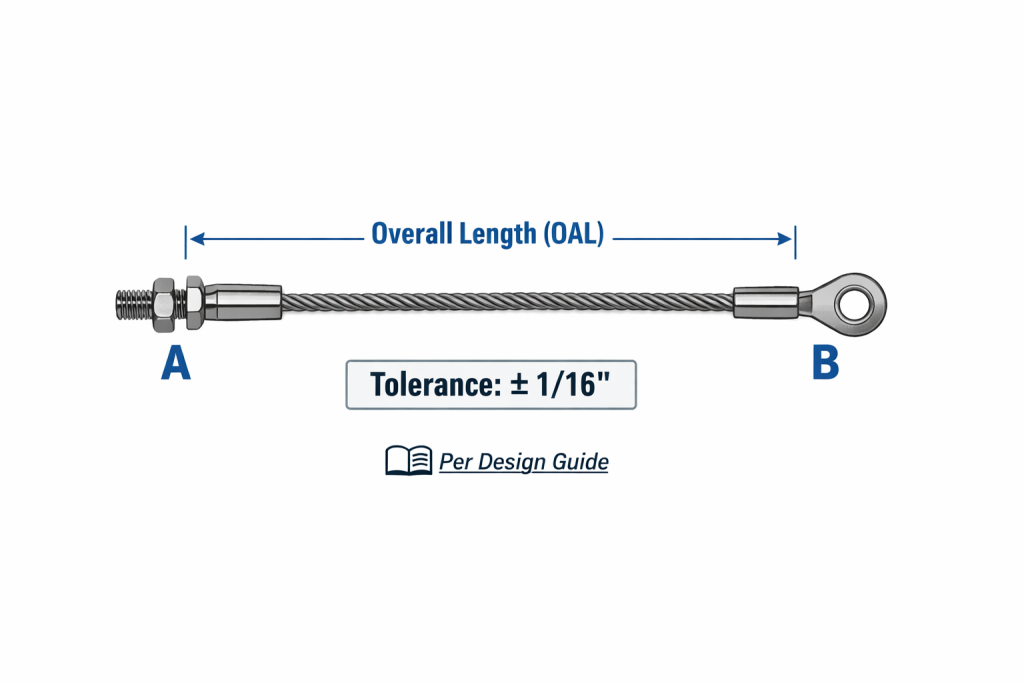

3. Define Length & Tolerances

Once cable and fittings are selected, we finalize the details that ensure a proper fit in your application. This includes:

- How we measure the assembly

- What tolerances we hold

These factors are guided by our wire rope design guides—covering tolerances, measuring points, cable construction, and recommended best practices for new assemblies.

Design Tips:

- The more we know up front about load, routing, and how you measure length, the faster we can move from quote to production-ready print.

Need a Starting Point?

Send us your print, sample, or basic requirements and our engineering team will help you refine the right cable size, construction, fittings, and tolerances.

Key Features & Benefits

Key features, advantages and customer benefits of Tyler Madison’s wire rope cable assemblies.

High-Strength Steel Cable

Steel and stainless steel wire rope constructions engineered for high tensile strength and long-term reliability under load.

Coating & Corrosion Protection

Bare or polymer-coated cable options to handle abrasion, moisture, chemicals, and outdoor exposure.

Precise Fit & Tolerances

Assemblies are cut, swaged, and measured to tight tolerances, helping ensure smooth fit with your mating components and fixtures.

Low Maintenance Durability

Quality materials, controlled swaging, and proper cable selection help reduce stretch, wear, and maintenance over the life of the assembly.

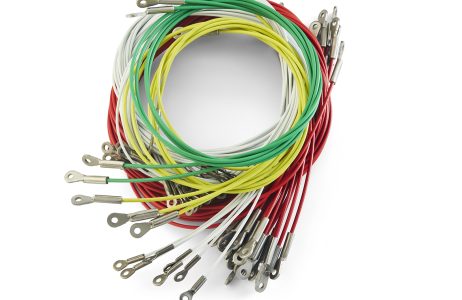

Visualize Your Next Wire Rope Cable Assembly

See how Tyler Madison turns specs into real-world solutions—from simple straight-pull tethers to multi-leg assemblies with complex hardware. Cables engineered for your application. Request a custom steel cable assembly.

Wire Rope & Custom Cable Assemblies Manufacturer

Tyler Madison is a custom cable assembly manufacturer building wire rope assemblies and custom cable assemblies for demanding mechanical applications. Whether you are refining an existing design or launching a new product, our team helps you confirm requirements, select the right materials and terminations, and move from questions to a clear quote fast.

Wire Rope Assemblies Built to Spec

We manufacture wire rope assemblies in stainless or galvanized steel, with bare or coated finishes, and a wide range of end fittings and hardware options based on your load, environment, and connection points. Expect repeatable lengths, consistent tolerances, and practical design guidance that keeps your assembly reliable in the real world.

Custom Cable Assemblies From Prototype to Production

As a custom cable assembly manufacturer, we support custom cable assemblies at every stage, including early prototypes, small runs, and long-run production programs. If you have a print, sample, or even a concept in progress, we can help you finalize specs and build an assembly that fits your mating components and performs as intended.

What you can expect when you partner with us:

- Expert support that helps you choose the right cable, fittings, and hardware for your application

- Design guidance to reduce rework and speed up approval

- Clear pricing and efficient quotes based on your specs and quantity

- Manufacturing support for prototypes through production and kitting when needed

Related Products & Services

If your project includes more than wire rope assemblies, Tyler Madison can support the full build. As a custom cable assembly manufacturer, we help customers source the right cable, coating, terminations, and related components so everything fits, functions, and holds up in the field.

At Tyler Madison, we also manufacture things like wire rope lanyards, push-pull controls, Bowden & Conduit assemblies, cable railing systems and other related wire rope hardware and end fittings. No matter that type of mechanical product that you are building or fixing, it’s likely that you can find all the cable and wire rope you need at Tyler Madison.

Wire Rope Assembly FAQs

Wire rope assemblies are configurations composed of several strands of metal wire twisted together to form a strong, flexible, and durable cable. Below are some key aspects of wire rope assemblies.

Do you manufacture custom cable assemblies?

Yes. Tyler Madison is a custom cable assembly manufacturer specializing in wire rope assemblies and custom cable assemblies built to spec.

What is a wire rope cable assembly?

A wire rope cable assembly is a length of wire rope that’s been cut, fitted with mechanical end terminations and/or hardware, and built into a functional unit. Assemblies are designed to do things like lift, support, restrain, or guide loads in mechanical systems.

What sizes and materials do you offer?

Tyler Madison typically works with cable sizes from about 3/64″ up to 3/8″ in diameter, with approximate breaking strengths from 270 lbs to 14,400 lbs, depending on construction. Common materials include galvanized and stainless steel, with bare or polymer-coated finishes (PVC, nylon etc).

Which industries use your wire rope assemblies?

We supply custom cable assemblies to OEMs in manufacturing, construction, aircraft, appliances, automotive, boating, furniture, farm equipment, lawn and garden, lighting, machinery, medical, security, sporting goods, toys, windows, and more.

What information do I need to design a new assembly?

Our engineers specialize in steel cable design and can help you choose the right wire rope construction, diameter, and end fittings for your application. Before we start it helps to know:

- Estimated annual or lot quantity

- Required load and safety factor

- End fittings or hardware that might work

- Whether the cable should be bare or coated (and any color requirements)

- Overall length and where we should measure from

- Length tolerances

- Desired cable construction and bend radius

If you’re not sure on one of these, our team can help you work through the options.

What are the components of a cable assembly?

A typical cable assembly includes:

- Conductors (copper or aluminum wires)

- Insulation layers around each wire

- Shielding (braid, foil) for noise protection

- Connectors or terminations (e.g. plugs, sockets, crimped ends)

- Outer jacket for environmental and mechanical protection

Optional components: heat-shrink tubing, strain relief, labels

What are typical lead times?

Lead times depend on complexity and quantity, but many projects can be produced in roughly a two-week window once the design is approved, with expediting available for urgent orders.

What is the cable assembly manufacturing process?

The manufacturing process typically includes:

- Design review and bill of materials (BOM) preparation

- Wire cutting and stripping to spec

- Cable grouping and assembly into subunits (if required)

- Adding shielding and insulation components

- Connector crimping, soldering, or termination

- Testing: continuity, insulation resistance, and visual inspection

- Labeling and packaging for shipment or installation

What are mechanical wire rope assemblies used for?

Mechanical wire rope assemblies are used anywhere you need to support, secure, guide, or move a load. Typical functions include:

- Maintaining tension and preventing unwanted movement

- Adjusting, regulating, or fine-tuning components

- Connecting, securing, and restraining parts or equipment

- Hanging, supporting, suspending, and containing loads

- Lifting, pulling, and retrieving in material handling

- Sliding, steering, and stopping moving parts

What are typical applications of a wire rope cable assembly?

Wire rope cable assemblies provide reliable performance in high-load or harsh environmental conditions. They’re commonly used in: Industrial automation and robotics, Marine and offshore equipment, Mining and construction machinery, Cranes, lifts, and material handling systems, Oil & gas and energy infrastructure.

Ready to Design Your Next Wire Rope Assembly?

Send your print, sample or basic requirements. We will review the details, help recommend the best build and provide a fast quote.