Here at Tyler Madison, we fabricate a wide variety of handles and end fittings to complement the wire rope controls and assemblies we construct for our customers. Cable handles and end fittings are found on push-pull cables/push-pull control cables, release cables, chokers, throttle cables and more.

Some of the main purposes of push-pull knobs and handles are for:

• Adjusting

• Actuating

• Accelerating

• Regulating

• Releasing

These end fittings offer confidence, precision and security to their user and their application.

We make most of our push-pull knobs and wire rope handles with a shell of phenolic resin or a similar composite. Such compounds create strong, chemically impervious and thermally stable hardware that is easy to grip without pain. This is a significant advantage if and when you need to tightly grip your assembly. If you require a custom product material or coating, we’re happy to discuss your needs and come up with a solution that works for you. We can also produce custom handles and knobs that meet different standard requirements, including those of Mil-spec cables (military cables) and aircraft cable assemblies.

Our most popular cable handles are t-handles. For details and size charts, keep reading.

T-Handle

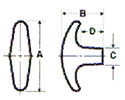

Wider than regular handles, T-handles are superior to regular handle fittings in a number of ways. First, they are capable of delivering greater torque, while requiring less energy. T-handle pull cables also provide a comfortable two finger grip. All in all, they are easy to use and durable. We offer our T-handles in a variety of different sizes and dimensions. Check out the chart below for details and, of course, reach out to us for information.

| T-Handle

|

Push-Pull Assembly End Fitting

Push-pull assembly end fittings, as one might assume, attach to the end of the outer sheath (also called conduit) of a push-pull cables assembly. Push-pull assemblies are control cables used to transmit force in two directions. The choke cable on a lawn mower engine is, for example, a push-pull assembly. In addition to lawn and garden, you can find push-pull cable assemblies in automotive, aviation, exercise, medical and office applications.

Push-pull cable assembly end fittings are essential to properly securing the assembly to a mount. We usually achieve this through the use of threaded bolts and nuts or the use of a snap ring. Without the right end fittings, a push-pull assembly could easily deflect under tension and cause a system failure or complete loss of control.

For your convenience, we offer push-pull knobs and handles and end fittings in a wide variety of standard configurations and stock material. We have an extensive inventory of stock components, like push-pull handles. However, we also welcome requests for custom work! To ensure expediency and the highest quality parts, we employ a group of local machinists to produce specialty fittings.

Our push-pull handles and knobs are perfect for wire rope assembly use in countless industries. Our customers come to us from leading companies in industries such as:

|

|

We look forward to working with you, no matter your industry.

ABOUT US

Tyler Madison, Inc. is a Minnesota-based company that specializes in everything related to wire rope cable assemblies and push-pull knobs. We offer both standard and custom push-pull cable controls, wire rope fittings, wire rope lanyards, machined end fittings and more. Our highly skilled personnel is supported by access to the latest technology and state-of-the-art in-house equipment. We will work with you every step of the way, from design and prototype to post-delivery. For reasonably priced quality assistance in designing, engineering and manufacturing the perfect mechanical cable assemblies, contact us today.